Description

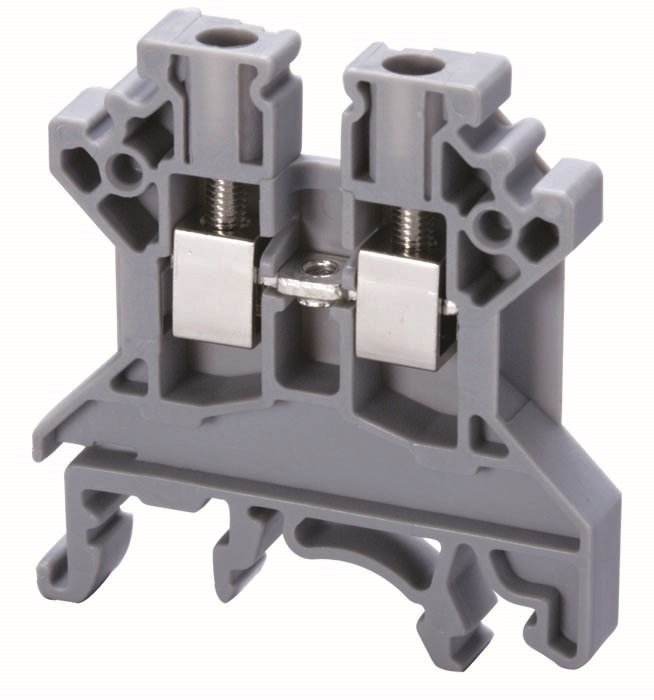

Disconnecting Type Neutral Links in Electrical system

- Disconnecting type neutral links in an electrical system refers to the separation or isolation of the neutral connection in a power distribution setup. The neutral link, which is typically connected to the ground (earth), is crucial in carrying unbalanced current back to the power source and ensuring safety and proper functioning of the system.

Technical Specifications

- Insulating Material : Polybutylene Terephthalate (PBT) for 16/32A, 63A and Phenol formaldehyde resin (Bakelite) for 100A

- Rated operating voltage : 500 V. AC

- Rated and uninterrupted current : 16/32A, 63A and 100A

- Ambient temperature : -10 °C to 55 °C

- Rated operating frequency : 50 Hz/60 Hz

- Rated impulse voltage : 2.5 Kv for one minute

- Insulation resistance : > 20 Mega Ω

We have developed a new range of Neutral links which can be mounted on the directly on the DIN channel, instead of the regular screw mounting. This saves considerable amount of time during panel assembly.

Why Disconnecting a Neutral Link may be required

• Maintenance or Testing: To safely perform maintenance, troubleshooting, or testing on a part of the electrical system, disconnecting the neutral link ensures the safety of personnel and equipment.

• System Isolation: In cases where part of the system needs to be isolated, for example, when performing insulation resistance testing (megger testing) or checking for ground faults, disconnecting the neutral link is necessary to avoid interference from the neutral-to-ground connection.

• Upgrading or Modifying Electrical Circuits: During changes to the system (e.g., installing new circuits or upgrading existing ones), disconnecting the neutral link prevents any unintended back feeding or grounding issues that may arise during modifications.

Risks and Precautions

Disconnecting a neutral link should be done carefully, as it can create potential safety hazards or disrupt system operation.

- Unbalanced Loads: In a three-phase system, the neutral wire carries the imbalance of currents from the different phases. Disconnecting it without turning off the phases can lead to uneven voltage distribution and possible equipment damage.

- Safety Grounding: The neutral is typically bonded to the earth ground at one point (in the main distribution panel). If you disconnect the neutral, you are breaking this grounding connection, which can leave parts of the system ungrounded and dangerous.

- Electrical Shock Risk: The neutral is considered a current-carrying conductor, so when disconnected, the neutral point might carry voltage under certain conditions, especially in systems with an unbalanced load or fault. Extreme care must be taken to avoid accidental contact.

Steps to Safely Disconnect a Neutral Link

Disconnecting the type neutral link must be done carefully and with the correct procedures to ensure system safety and avoid hazards. It is generally a task for qualified electricians, given the risks involved with grounding, load imbalance, and shock hazards.

- Turn Off Power: Ensure all power to the system is turned off at the main breaker before attempting to disconnect the neutral.

- Test for Voltage: Verify with a voltage tester that no voltage is present between the neutral and ground before disconnecting.

- Disconnect Only in Approved Areas: Typically, neutral links should only be disconnected at the main panel or approved distribution points to avoid floating neutral conditions downstream.

- Use Proper Insulation: After disconnection, ensure the neutral link is properly insulated to prevent accidental contact with live parts or ground.

- Rebonding the Neutral: When reconnecting, ensure the neutral is properly bonded to the grounding system according to local electrical codes.