Description

Application

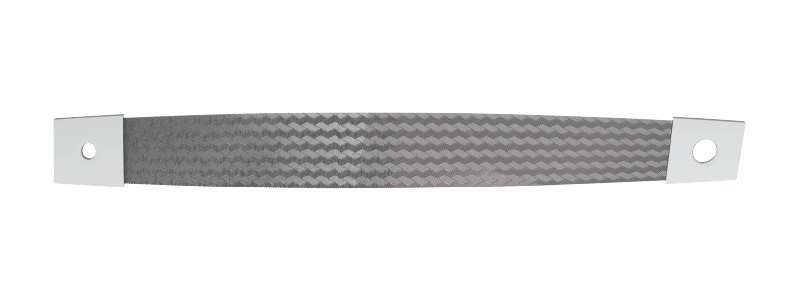

Flexible braided copper and tinned copper straps are used as grounding braids, primarily for batteries, earthing, and bonding applications where high flexibility and current-carrying capacity are essential.

Standards

Manufactured in accordance with DIN 72333 Part 3 and equivalent RR specifications. These standards define the construction and performance of flexible braided copper and tinned copper tapes.

Cable Construction

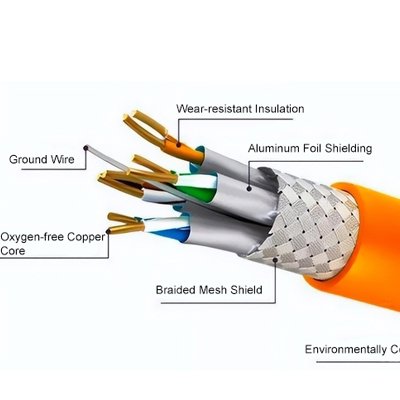

- Conductor: Annealed electrolytic grade copper wires, plain or tinned.

- Wire Diameter: 0.16 to 0.20 mm (standard range), available up to 0.30 mm as per RR specification.

- Surface Finish: Plain/Bare Copper or Tinned Copper.

- Construction: Braided strands of fine copper wires ensuring maximum flexibility and current transfer efficiency.

- Packing: Supplied in rings, spools, or wooden drums as per customer requirement.

Technical Data

Flexible braided copper/tinned copper tapes provide excellent flexibility and electrical conductivity. They are ideal for use in grounding, bonding, and current transfer applications across electrical panels, switchboards, and battery terminals.

Cable Design Parameters

Kindly complete the part numbers by adding the suffix (in place of ‘c’) for the conductor type required:

0 = Plain/Bare Copper, 1 = Tinned Copper.

| Part Number | Nominal Cross Section (Sq.mm) | No. of Wires | Strand Diameter (mm) | Width (mm) | Thickness (mm) |

|---|---|---|---|---|---|

| 12090101000c | 35 | 36 × 48 | 0.16 | 25 | 3.0 |

| 12090102000c | 50 | 36 × 69 | 0.16 | 33 | 3.2 |

| 12090103000c | 70 | 48 × 72 | 0.16 | 35 | 4.5 |

| 12090104000c | 14 | 36 × 13 | 0.20 | 18 | 1.5 |

| 12090105000c | 16 | 36 × 15 | 0.20 | 20 | 1.6 |

| 12090106000c | 21 | 36 × 19 | 0.20 | 22 | 2.0 |

| 12090107000c | 25 | 36 × 22 | 0.20 | 22 | 2.5 |

| 12090108000c | 35 | 36 × 31 | 0.20 | 25 | 3.0 |

| 12090109000c | 50 | 48 × 33 | 0.20 | 33 | 3.2 |

| 12090110000c | 70 | 48 × 47 | 0.20 | 35 | 4.5 |

Flexible Braided Copper & Tin Copper Tapes as per RR Specification

Technical Data

Material: Annealed electrolytic grade copper wire. Wire Diameter – 0.16 to 0.2 mm.

Packing: In rings, spools, or wooden drums.

Construction and Application

Flexible braided copper/tin copper tapes consist of wires with a stringer wire diameter of 0.12 to 0.3 mm.

Surface: Plain Copper or Tinned Copper.

Cable Design Parameters

Kindly complete the part numbers by adding the suffix (in place of ‘c’) for the conductor type required:

‘

| Part Number | Nominal Cross Section (Sq.mm) | No. of Wires | Strand Diameter (mm) | Width (mm) | Thickness (mm) |

|---|---|---|---|---|---|

| 12070111000c | 40 | 48 × 48 | 0.15 | 30 | 2.5 |

| 12070112000c | 55 | 48 × 64 | 0.15 | 33 | 2.5 |

| 12070113000c | 20 | 36 × 8 | 0.30 | 20 | 2.0 |

| 12070114000c | 30 | 36 × 12 | 0.30 | 25 | 2.4 |

| 12070115000c | 40 | 36 × 16 | 0.30 | 30 | 3.0 |

| 12070116000c | 50 | 36 × 20 | 0.30 | 30 | 3.5 |