Description

Application

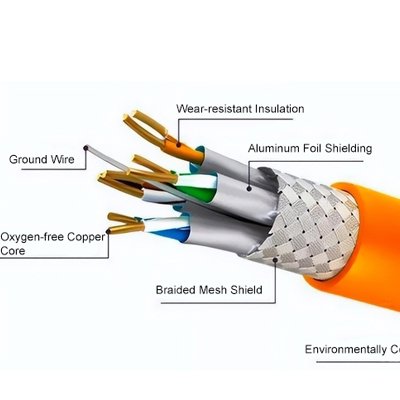

The **PVC insulated and sheathed 3 core flat cables** are mainly used in pump connections. They are also widely utilized in many industrial applications. The sheath is specially designed to resist tough and difficult outdoor conditions and offers excellent resistance to water.

Technical Data

• Voltage Grade: Upto and including 1100V.

• Approvals: IS 694 marked, FIA/TAC.

• Conductor: Electrolytic grade annealed copper.

• Conductor Detail: Strands of electrolytic annealed plain copper are multi-drawn for uniformity of resistance, dimension and flexibility.

• Core Colour: Red, yellow (centre core), blue.

• Sheath Colour: Black.

• Packing: Standard packing of 100 mtr. in coils. Longer length available on request.

Variants Available (Specifications)

| Product Type | Specifications |

|---|---|

| PVC 70°C | IS 694, IS 8130 Class 2 (1.5 & 2.5 Sq. mm), for others class 5, IS 5831 Type A insulation & ST-1 sheath. |

| HR 85°C | IS 694, IS 8130 Class 2 (1.5 & 2.5 Sq. mm), for others class 5, IS 5831 Type C insulation & ST-2 sheath. |

Cable Design Parameters

Kindly complete the part numbers for these cables by adding the suffix (in place of ‘y’) for the cable type:

1 – PVC 70°C

3 – PVC HR 85°C

| Part Number | Nominal Cross Sectional Area (mm²) | Conductor construction (No./Max. dia of strands) (mm) | Conductor resistance at 20 °C (Ω/km) Max. | Nominal Insulation Thickness (mm) | Nominal Sheath Thickness (mm) | Approx. overall dimensions (W X H) (mm) ± 0.5 mm | Current carrying capacity (Ampere) |

|---|---|---|---|---|---|---|---|

| 0118110102y1 | 0.5 | 16/0.2 | 39.0 | 0.6 | 0.9 | 9.60 X 4.90 | 4 |

| 0118110202y1 | 0.75 | 24/0.2 | 26.0 | 0.6 | 0.9 | 10.5 X 5.20 | 7 |

| 0118110302y1 | 1 | 32/0.2 | 19.5 | 0.6 | 0.9 | 11.0 X 5.40 | 12 |

| 0118110402y1 | 1.5* | 22/0.3 | 12.1 | 0.6 | 0.9 | 12.0 X 5.6 | 18 |

| 0118110502y1 | 2.5* | 36/0.3 | 7.41 | 0.7 | 1.0 | 13.0 X 6.2 | 24 |

| 0118110602y1 | 4 | 56/0.3 | 4.95 | 0.8 | 1.0 | 15.3 X 7.1 | 28 |

| 0118110702y1 | 6 | 84/0.3 | 3.30 | 0.8 | 1.1 | 19.2 X 8.4 | 36 |

| 0118110802y1 | 10 | 140/0.3 | 1.91 | 1.0 | 1.4 | 24.2 X 10.4 | 48 |

| 0118110902y1 | 16 | 126/0.4 | 1.21 | 1.0 | 1.4 | 29.0 X 12.4 | 64 |

| 0118111002y1 | 25 | 196/0.4 | 0.78 | 1.2 | 2.0 | 36.5 X 15.7 | 80 |

| 0118111102y1 | 35 | 276/0.4 | 0.554 | 1.2 | 2.0 | 40.5 X 17.2 | 100 |

| 0118111202y1 | 50 | 396/0.4 | 0.386 | 1.4 | 2.2 | 46.5 X 19.3 | 130 |

| 0118111302y1 | 70 | 360/0.5 | 0.272 | 1.4 | 2.2 | 52.0 X 21.0 | 192 |

| 0118111402y1 | 95 | 480/0.5 | 0.206 | 1.6 | 2.4 | 61.0 X 24.5 | 230 |

*Note: For nominal cross sectional areas 1.5 mm² and 2.5 mm², the specification is IS 8130 Class 2; for all others, it is Class 5.

Current Rating Conversion Factor for Deviating Ambient Temperature

Multiply the current carrying capacity of the cable by the factors given below for various ambient temperature conditions.

| Ambient Temperature (°C) | Derating Factor |

|---|---|

| 25 | 1.25 |

| 30 | 1.16 |

| 35 | 1.09 |

| 40 | 1.00 |

| 45 | 0.90 |

| 50 | 0.81 |

| 55 | 0.74 |

| 60 | 0.68 |